How Synthetic Fibers Came to Dominate the Upholstery & Drapery Industry

Posted by Decorative Fabrics Direct on Mar 19th 2025

Posted by Decorative Fabrics Direct on Mar 19th 2025

Posted by Decorative Fabrics Direct on Mar 13th 2025

Apr 12th 2023

Mar 18th 2023

A double rub rating is not applicable to a fabric used for bedding, curtain, drapery or other applications where the fabric is not subjected to abrasion. A double rub rating applicable to fabric used for upholstery is obtained from an industry test that measures fabric resistance to typical abrasion that is expected from the use of upholstered furniture.

Under 5000 Double Rub Rating or code "LD" is suitable for home decor light duty upholstery use (not daily use, more for decorative appeal).

5000 - 14900 Double Rub Rating or code "MD" is suitable for medium use home decor upholstery applications such as living rooms.

15000 - 29900 Double Rub Rating or code "RD" is suitable for everyday regular and heavy use home decor upholstery applications.

30000 and Above Double Rub Rating or code "HD" is suitable for residential and commercial upholstery subjected to "extreme use".

Code "LDO" indicates a selection of fabric that is only recommended for 'light duty outdoor' upholstery applications where cushions do not receive regular use and can be easily removed and stored away from harmful UV light when not in use. These selections are not intended for normal indoor furniture upholstery as they are not constructed to withstand the abrasion of regular use. If you are in need of a more durable outdoor fabric that can also be used for indoor upholstery, we recommend a High Performance Indoor-Outdoor Fabric from Sunbrella, Bella-Dura and Covington.

The surface wear of a fabric caused by rubbing and contact with another fabric. Association For Contract Textiles "ACT" GUIDELINES General Contract Upholstery ASTM D4157-02 (ACT approved #10 Cotton Duck) 15,000 double rubs Wyzenbeek method ASTM D4966-98 (12 KPa pressure) 20,000 cycles Martindale method Heavy Duty ASTM D4157-02 (ACT approved #10 Cotton Duck) 30,000 double rubs Wyzenbeek method ASTM D4966-98 (12 KPa pressure) 40,000 cycles Martindale method End use examples of heavy-duty installations where upholstery fabrics rated at 30,000 double rubs should be appropriate are single shift corporate, hotel rooms/suites, conference rooms and dining area usage.

ACT acknowledges that there are extreme wear situations that may require higher levels of abrasion resistance. End use examples that may require higher than 30,000 double rubs include: 24 hours transportation terminals, 24 hour telemarketing, 24 hour healthcare emergency rooms, 24 hour casino gambling areas, and such public gathering places as theatres, stadiums, lecture halls and fast food restaurants. It is strongly suggested that double rubs exceeding 100,000 are not meaningful in providing additional value in use. Higher abrasion resistance does not necessarily indicate a significant extension of the service life of the fabric.

The Wyzenbeek and Martindale tests are the two methods commonly used to predict wear-ability. Actual performance is determined by many factors such as fiber content, weaves, finishes, furniture design, maintenance, cleaning, and usage. Durability of an upholstery fabric is a complex interaction (combination) of a number of performance tests that, in addition to abrasion, includes seam slippage, pilling, tensile strength, and usage. There is no correlation between the Wyzenbeek and Martindale tests so it is not possible to estimate the number of cycles that would be achieved on one test if the results from the other test were known.

TEST METHODS ASTM D4157-02 Oscillatory Cylinder (Wyzenbeek) The ASTM D4157-02 is a test of the American Society of Testing and Materials. A Wyzenbeek machine is used for this test allowing samples of the test fabric to be pulled tight in a frame and held stationary. Individual test specimens cut from the warp and weft direction are then rubbed back and forth using an ACT approved #10 cotton duck fabric* as the abradant. The number of double rub cycles achieved before two yarn breaks occur or noticeable wear is observed is recorded as the fabrics abrasion rating.

The wire screen abradant is recommended by ACT for use with vinyl and polyurethane coated upholstery and may also be used for testing 100% olefin fabrics.

ASTM D4966-98 Martindale The ASTM D4966-98 is a test method of the American Society of Testing and Materials (ASTM). This is an oscillating test. Fabric samples are mounted flat and rubbed in a figure eight like motion using a piece of worsted wool cloth as the abradant. The number of cycles that the fabric can endure before fabric shows objectionable change in appearance (yarn breaks, pilling, holes) is counted. Number of cycles determines abrasion rating.

DC - DRY CLEAN ONLY

MS - MACHINE WASHABLE ON GENTLE CYCLE

OP - OUTDOOR PERFORMANCE (for most High Performance Indoor/Outdoor Fabrics, other than Bella Dura Home) - Remove as much loose dirt as possible. A mild detergent mixed with lukewarm water should be tried first to clean the fabric. For more stubborn stains, bleached can be used as follows:

Prepare a solution of one cup of bleach and one fourth cup of mild soap per gallon of cold to lukewarm water. Spray the solution on entire area to be cleaned and allow 15 minutes to soak into the fabric. Clean the entire surface area with a sponge, clean towel or very soft bristle brush to avoid abrading the fabric. Rinse thoroughly to remove all soap residue, then air dry. For severe cases of mold/mildew growth, bleach quantities may be increased. It is best to clean the entire surface area of the fabric to avoid water rings and stains.

OP - OUTDOOR PERFORMANCE (for Bella Dura Home Fabrics) - Cleanup involves a mild soap mixed 1 part soap to 10 parts water and a soft brush. When necessary, and for stubborn stains, Bella Dura Home fabrics are bleach cleanable with a 1 part bleach to 4 parts water mixture. Remember to always rinse with clear water to remove all residue. Remaining residue attracts dirt, so if proper rinsing has not occurred, fabrics will get soiled again much more quickly. Also, never dry clean, use an iron or steam this product. Allow this product to air dry.

R - This fabric can be cleaned with almost any household cleaner -- even pure bleach will not damage this fabric! Most stains can be blotted and cleaned with just water, but we recommend mixing some bleach in the solution to kill any bacteria that may grow. Whatever cleaning product you use, it is important to thoroughly rinse the fabric with clean water and allow the fabric to air dry. Fabrics with a R cleaning code are manufactured for upholstery use and have a fabric back coating for extra strength. Therefore, do not machine wash as this could damage the backing.

RP - This multi-purpose fabric is suitable for slipcover applications and has no fabric back coating. Fabrics that are designated with a RP cleaning code are machine washable. This fabric is not only soft and beautiful, but also durable, inherently stain resistant, and bleach cleanable...even dark colors. This fabric should be washed on a delicate cycle with cold water accompanied with laundry detergent and bleach, if necessary. After the wash is complete, dry your fabric on LOW heat for no more than 10 minutes. Exposure to high temperatures will damage olefin. Also, do not iron. For tougher stains pretreat soiled area with a bleach and water mixture.

S - SOLVENT CLEANER - Spot clean with a mild water-free solvent or dry cleaning product. Clean only in a well ventilated room and avoid any product that contains carbon tetrachloride or other toxic materials. Pretest a small area before proceeding.

W - WATER BASED CLEANER - Spot clean using the foam from a water-based cleaning agent such as a mild detergent or non solvent upholstery shampoo product. Apply foam with a soft brush in a circular motion. Vacuum when dry. Pretest a small area before proceeding.

WS - WATER-SOLVENT CLEANER - Spot clean with a mild solvent, an upholstery shampoo, or the foam from a mild detergent. When using a solvent or dry cleaning product, follow instructions carefully and clean only in a well ventilated room. Avoid any product that contains carbon tetrachloride or other toxic materials. Pretest a small area before proceeding.

X - VACUUM ONLY - Clean this fabric only by vacuuming or light brushing to prevent accumulation of dust and grime. Water-based foam cleaners or solvent-based cleaning agents of any kind may cause excessive shrinking, staining or distortion of the surface, and therefore should not be used. These recommendations and codes were developed by fabric specialists. However, because of the various ways that fabric can be stained or damaged, there is no guarantee that the results will be completely successful. These suggestions are provided as a service only. To help prevent overall soil, frequent vacuuming or light brushing to remove dust and grime is recommended. Use a professional furniture cleaning service when an overall soiled condition has been reached.

Most of our fabric selections (with the exception of faux leather and leather) are eligible for our free shipping coupon promotion and the item page will indicate eligibility by the display of a coupon icon: ![]() . To qualify for free shipping via FedEx Ground service, an eligible item must be included on a fabric purchase of $199 or more and the shipping destination must be a US state other than Hawaii or Alaska. Simply enter coupon code

. To qualify for free shipping via FedEx Ground service, an eligible item must be included on a fabric purchase of $199 or more and the shipping destination must be a US state other than Hawaii or Alaska. Simply enter coupon code

Note- Samples are free of shipping charges to all US & Canadian destinations via First Class US Mail, no coupon is required.

We apologize that our order processing has not been consistent during this pandemic and please know that we are working very hard to return to quick and consistent order processing. Our distribution center is operational and is currently processing orders as indicated below:

We apologize that our order processing has not been consistent during this pandemic and please know that we are working very hard to return to quick and consistent order processing. Our distribution center is operational and is currently processing orders as indicated below:

►In Stock Yardage Orders are being processed for shipment from our Atlanta Distribution Center within 2 business days.

►Special Orders are being processed for shipment from our Distribution Center or the Fabric Mill within 2-10 business days (each individual fabric page displays a specific estimate of the days until shipment). Some items will display that the mill is temporarily closed due to the pandemic and in those cases we are unable to provide an expected special order shipping date but will keep you posted.

►Sample Orders are being processed for shipment within 7 business days.

The supplier of this item has temporarily closed its distribution center due to the coronavirus pandemic. If you place a yardage order we are unable to provide an expected shipping date but your order will be first in queue when the mill reopens and we will keep you posted and will notify you before shipping.

We apologize for the inconvenience and hope to return to normal service soon.

The measurement of a fabric's performance when it is exposed to specific sources of ignition.

Note: Association For Contract Textiles "ACT" guidelines specify different flammability tests dictated by the intended end use for the fabric.

ACT GUIDELINES:

Upholstery

California Technical Bulletin #117 Section E –

Class 1 (Pass)

Direct Glue Wallcoverings

ASTM E 84-03 (Adhered Mounting Method) –

Class A or Class 1

Wrapped Panels and Upholstered Walls

ASTM E 84-03 (Unadhered Mounting Method) –

Class A or Class 1

Drapery

NFPA 701-89 (Small Scale)* – Pass*NFPA 701-99 Test #1 is being phased in at this time, but is not yet cited in all relevant codes. Therefore, the small-scale test remains the ACT standard until further notice.

NFPA 701-99 (Small Scale)

California TB #117 Section E

California Technical Bulletin #117

Section E* – Class 1 (Pass)

The California TB #117 Section E is a test method of the California Bureau of Home Furnishings and Thermal Insulation. It is a vertical flame test measuring the ease of ignition and the burning rate when a small open flame hits the surface of the test fabric for 1 second. A Class 1 (Pass) rating is assigned if:

1. A 5.0" section of the fabric is consumed in 3.5 or more seconds (less than 3.5 seconds is a failure). For raised surface fabric, the minimum burn time is increased to 4.0 seconds.

2. The fabric does not ignite.

ASTM E 84-03 Tunnel Test

The ASTM E-84 test is a test method of the American Society for Testing and Materials (ASTM). Commonly called the Tunnel Test, this test can be performed under two different methods adhered or non adhered where the only difference is in specimen preparation:

Adhered: The fabric is bonded to either a CA board substitute or gypsum board. This is the prescribed method for wall coverings whose actual use will be adhered .

Non adhered: If the fabric is a panel fabric or upholstered walls, it is tested in a frame without being bonded to any other material.

In each instance (adhered and non adhered), the fabric is placed in the ceiling of the test tunnel and subjected at one end to a high intensity flame which spreads over the first 4.5 feet of the 24 foot test specimen.

The distance of flame front progression and total burning time are used to calculate a flame spread index . Smoke monitors are used to calculate a smoke developed value. The flame spread index and smoke developed value are calculated from the results of the test fabric compared to the characteristics of cement board and red oak materials resulting in the indexes.

Typically, the code classes are as follows:

Class A: Flame Spread Index of 25 or less and Smoke Developed value of 450 or less

Class B: Flame Spread Index of 26 to 75 and Smoke Developed value of 450 or less

Class C: Flame Spread Index of 76 to 200 and Smoke Developed value of 450 or less

Caution: The ASTM E 84 test is only valid if the textile or vinyl wall covering is used in a sprinklered occupancy. If not, the Room Corner Test (NFPA 265 for textiles; and NFPA 286 for vinyl) is mandated in many jurisdictions.

NFPA 701-89 (Small Scale)

The NFPA 701-89 (Small Scale) is a test method of the National Fire Protection Agency. It measures the ignition resistance of a fabric after it is exposed to a flame for 12 seconds. The flame, char length and flaming residue are recorded. The fabric will pass the test if all samples meet the following criteria (if one sample fails the fabric fails):

1) An after flame of less then 2.0 seconds

2) An average char length of less than 6.5" or an individual specimen of 7.5".

3) The specimen does not continue to flame after reaching the floor of the test chamber

<

Note: NFPA 701-99 Test #1 is being phased in at this time, but is not yet cited in all relevant codes. Therefore, the small-scale test remains the ACT standard until further notice

Canadian and other International buyers are responsible for all applicable brokerage fees and duties which will be collected at delivery.

Colorfastness to Light is a material's degree of resistance to the fading effect of light.

Association For Contract Textiles "ACT" GUIDELINES

Upholstery: AATCC 16 Option 1 or 3-2003 Grade 4 minimum at 40 hours.

Wrapped Panels and Upholstered Walls: AATCC 16 Option 1 or 3-2003 Grade 4 minimum at 40 hours.

Drapery: AATCC 16 Option 1 or 3-2003 Grade 4 minimum at 60 hours.

TEST METHOD: AATCC 16 Option 1 or 3 – 2003*

The AATCC 16 Option 1 and 3 are test methods of the American Association of Textile Chemists and Colorists (AATCC). ACT recognizes both methods where the only difference is the light source being used. In AATCC 16 Option 1 a Carbon-Arc lamp is used as the light source and in AATCC 16 Option 3 a Xenon-Arc lamp is used. Under both methods a strip of fabric (part of which is protected by a special paper card) is placed in a fadometer and exposed to 40 hours of accelerated fading units (AFU). After the exposure the difference in color between the exposed and protected parts of the fabric are compared to the AATCC gray scale and the degree of fading is rated.

Grade 5 = no fading

Grade 4 = slight fading

Grade 1 = high degree of fading

We apologize, but for the next few weeks we will be unable to offer samples as we normally do, day in and day out. Unprecedented demand for samples has created a two week backlog for us to fill and we do not want to inconvenience any customers with new sample orders by this long of a delivery. We are shipping FABRIC orders, but at this time we must temporarily pause taking any new SAMPLE orders until we get back to our normal 2 to 3 day shipment policy. We anticipate we will be back on our regular delivery by the 22nd of this month and will accept sample orders again at that time. We do know that in some cases there are emergency and deadline situations, and we ask that you call our customer service department (888-633-2658) to advise us of such. We sincerely apologize, but felt being up front was the best way to handle the situation considering you, our valued customer.

California's Proposition 65 entitles California consumers to special warnings for products that contain chemicals known to the state of California to cause cancer and birth defects or other reproductive harm if those products expose consumers to such chemicals above certain threshold levels. When a manufacturer informs us that this warning is applicable to their product we will indicate such among the specifications on a specific item page. The general Proposition 65 notice is as follows: WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. For more information, visit www.P65Warnings.ca.gov

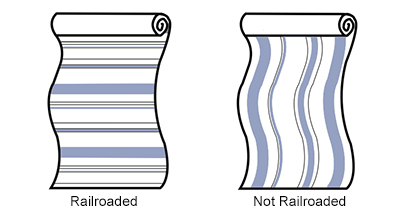

Railroaded fabrics are simply fabrics that have designs turned "sideways" on the roll. The process was developed to aid furniture manufacturers wishing to cut and sew covers on furniture without seams. Since most fabrics woven are approximately 54" wide, any furniture piece wider than 54" would require seaming two pieces of fabric together. Railroading solves this dilemma, now a cushion piece can be covered without seams no matter what the width. Railroaded fabric is very desirable by designers since they can be more creative. When using a railroaded product for drapery, be aware of the panel size in relation to the design.

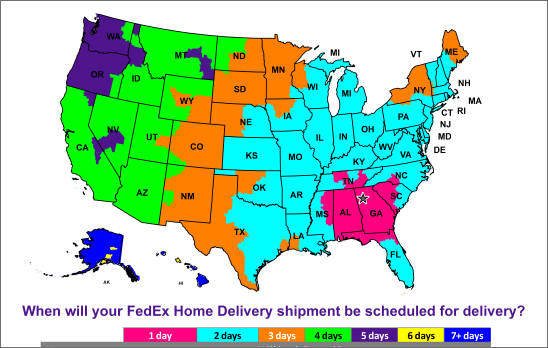

You will have the option to select various levels of expedited time definite shipping service during checkout. The map below shows expected transit days of the least expensive shipping options for FedEx Ground & Home Delivery service (1-7 days continental US) determined by your distance from our Atlanta Distribution Center. Please be aware that transit days are Monday - Saturday for most home deliveries and Monday - Friday for most business deliveries. Our Canadian customers can select UPS Standard Service which is approximately 6-7 transit days.

FEDEX GROUND & HOME SERVICE MAP BELOW:

We have entered into agreements with several of our suppliers allowing us to special order items for our customers directly from the mill when we otherwise do not stock or have a very low "in-stock" quantity at our Atlanta distribution center. Special order availability will be indicated on the item if it is applicable. The shipping date of a Special Order is most often within 2-10 business days, please look on the specific item page as the expected shipping time is noted.

Special Orders may be subject to a minimum quantity purchase and if so the minimum will also be indicated on the specific item page. It is very important to have seen a sample as special orders are non-cancellable and not returnable to the mill. To place an order for special order items please select the option to order yardage (or roll for wallpaper), enter the quantity needed for your project in the quantity box and click the add to cart button.

SURFACE PREPARATION

For best results all surfaces should be clean, smooth, dry and free of mildew. We do not recommend

using on textured surfaces, over existing wallpaper, brick, cinderblock, unpainted drywall or plaster.

HANGING INSTRUCTIONS

Measure the wall height and pre-cut strips to match the wall height, allow an extra 1-2 inches for

trimming

both the top and bottom. Make sure to align any design from strip to strip.

This means "STRAIGHT MATCH" designs are matched at the same height. It is where the left and

right edges of the wallpaper strip match in a straight horizontal line with the left and right edges

of the

next strip of wallpaper "HALF DROP" designs repeat across the roll half way down the vertical repeat

and must be taken into consideration when each strip is cut. Do not cut "HALF DROP" design strips

like

you would "STRAIGHT MATCH" or your strips will line up incorrectly.

Cut and trim product with a sharp razor knife changing the blade often to help maintain a

smooth

clean cut. Number the back of each strip as you go to keep your design in the correct order (only if

pattern

requires it).

Starting on the left side of your wall, measure out from the corner 20.5" (52.1 cm) and mark the wall lightly with a pencil. Put your level on this mark and draw a straight, level, vertical line. This is the guide for your first strip, it is important that it is straight.

Peel about 12" (30.5 cm) of the backing away from the paper. Apply the paper to the top of the wall, allowing 1-2 extra inches to overlap the ceiling which will be trimmed off later. Align the right side of the strip with your vertical line to your mark and lightly press the edge to the wall along the line. If needed, you can reposition to ensure a vertical seam. Working from top to bottom, pull the backing away from the paper as you evenly press the paper to the wall. Do not force the paper and be careful not to pull or stretch the product or the pattern will not align. For best results, we recommend having one person guide the paper at the top and along the seam, while the other holds the opposite edge away from the wall until the seams are aligned.

Using a plastic smoother, make your way down the strip in a back-and-forth motion, smoothing the material to the wall and pushing out any air bubbles.

Trim off the excess material at the ceiling and baseboard with a ruler and sharp razor knife.

Wallpaper rolls are generally considered to be between only 85 and 95 percent usable due to patterns that

need to be matched and the scraps generated in doing so. The smaller the pattern, the less extra wallpaper

that will be needed.

Your first step would be to measure the room that you intend to decorate. Measure both the length of

a wall in feet and the height of the wall in feet. Multiply the width by the height. This will give you the

square footage of that wall. Do this for all walls in the room and add up those measurements to get the

total wall square footage of that room. We suggest to not subtract for windows and doors as this is not

necessary. Why? When wallpaper is installed, it has to be trimmed around the doors and windows. In doing so,

this could require just as much wallpaper as a solid wall. Now that you have the total square footage,

don't forget to allow for extra and we suggest 10-15%, due to matching and scraps being created in the

installation process.

You can determine the number of rolls needed by dividing your total by 30.75, which is the square

footage in each of our Surface Style Collection wallpapers. If you calculate and get a fraction, remember to

round up to be safe.

We hope these guidelines are helpful and please remember these are general guidelines.